ISO 50001

Companies and Institutions aim at reducing their energy consumption. The drivers are often a combination of the following: desire to enhance corporate public image, compliance with Regulations, cost reduction, mitigation of rising energy costs, Corporate policy, reduction in GHG emissions etc.

Standard ISO 50001 and its companions (aka ISO 50k) were developed to guide Energy Management stakeholders and offer a systematic approach to establish processes.

Standard ISO 50001 aims at continuously improving energy performance and energy efficiency and to identify energy savings potential actions. It is now a universally recognized Standard for managing energy and providing a management strategy. With its consistent energy management methodology, the Standard offers a framework with traceable and verifiable procedures.

The ISO Organization summarizes the ISO 50001 Standard as as set of requirements that enable companies to:

- Develop a policy for more efficient use of energy

- Fix targets and objectives to meet that policy

- Gather data to better understand and make decisions concerning energy use

- Measure the results obtained

- Review the effectiveness of the policy

- Continually improve energy management

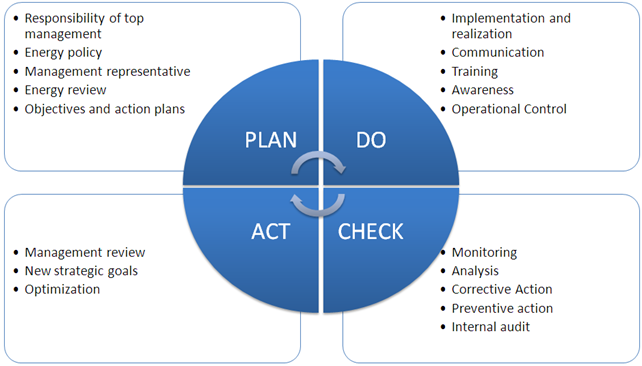

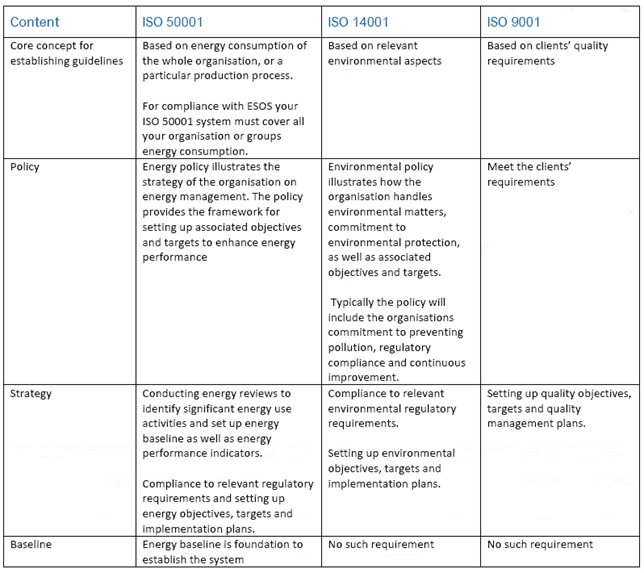

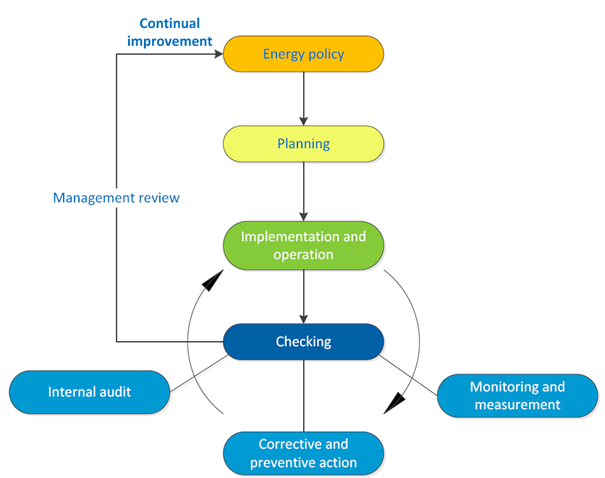

Like ISO 14001 and ISO 9001 management system standards, ISO 50001 follows the “Plan-Do-Check-Act” process for continual improvement. Since all three management systems standards are based on the PDCA cycle, and now share the same high-level structure, ISO 50001 can be integrated easily to these systems.

In the context of an Energy Management System (EnMs), the PDCA approach can be outlined as follows (source: iso.org):

- Plan: understand the context of the organization, establish an energy policy and an energy management team, consider actions to address risks and opportunities, conduct an energy review, identify significant energy uses (SEUs) and establish energy performance indicators (EnPIs), energy baseline(s) (EnBs), objectives and energy targets, and action plans necessary to deliver results that will improve energy performance in accordance with the organization’s energy policy.

- Do: implement the action plans, operational and maintenance controls, and communication, ensure competence and consider energy performance in design and procurement.

- Check: monitor, measure, analyze, evaluate, audit and conduct management review(s) of energy performance and the EnMS.

- Act: take actions to address nonconformities and continually improve energy performance and the EnMS.

While ISO 14001 provides a qualitative view at the significant environmental impacts, ISO 50001 aims at improving energy performance and is data-driven.

An added main feature of ISO 50001 is the energy baseline that must be built for the targeted site. Using energy consumption over selected periods of time (for example monthly), the site energy consumption is correlated with relevant parameters such as weather (via temperature, heating degree days, cooling degree days), production, turn over, raw materials, throughput, margin, etc.…These parameters will be later used as the “adjusting factors” to calculate a theoretical energy consumption – to be compared with the real consumption to evaluate the effect of actions which were implemented.

An Energy review must be conducted. Using a breakdown of the main energy usages, it can help prioritize targets to identify energy conservation actions.

The energy review also ensures that inventories are drawn up not only for consuming equipment, but also for sensors and measurement instrumentation. Ideally, the whole instrumention should be traceable, and the responsible Staff easily identifiable.

Using an accepted protocol for energy measurement and verification, energy consumption can be monitored and savings can be calculated (based on real consumption and baseline consumption adjusted with the appropriate adjusting parameters). Following the PDCA approach, corrective actions should be taken to ensure that energy performance is continuously improved.

Feel free to consult Planet Decarb experts. We will be happy to review of your requirements and prepare a gap analysis for you.