Decarbonization in a Nutshell

Climate change mitigation will require deep decarbonization – i.e. stepping into a whole new paradigm, where GHG emissions are drastically reduced. This means addressing all GHG emissions: carbon dioxide, methane, artificial fluorinated compounds and nitrous oxide.

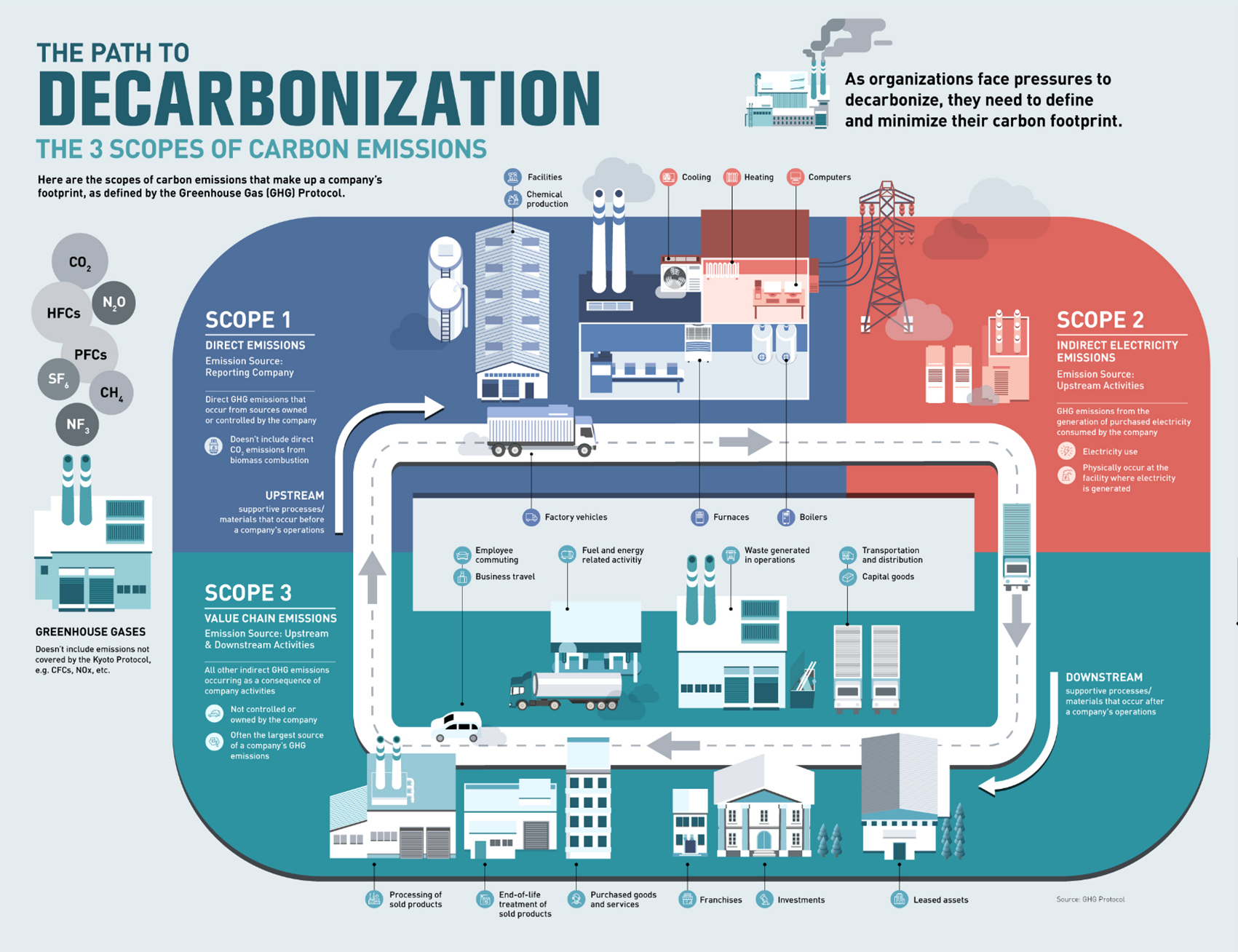

SCOPES OF CARBON EMISSIONS

The GHG Protocol classifies greenhouse emissions into three ‘scopes’ that include certain types of emissions depending on the location of carbon emissions, relative to the reporting company’s site of interest. Note that “carbon emissions” should refer to GHGs in general, and not only to carbon dioxide. Some Institutions make disctinction between CO2 emissions and GHGs (which include both CO2 emissions and other GHGs which are expressed as “CO2 equivalent emissions” of gases like fluorinated & nitrous substances.

Therefore, one should always state exactly what GHGs substances are covered in a Carbon emissions inventory.

| Scope | Scope 1 | Scope 2 | Scope 3 |

Type of emissions | Direct emissions from owned or controlled sources. Excludes direct emissions from biomass combustion. | Total emissions due to the generation/transformation of purchased energy (including all its related carbon emissions). | All indirect emissions (not included in Scope 2) that occur in the value chain of the reporting company, including both upstream and downstream emissions |

Examples | Heating fuel, natural gas, with combustion on-site, electricity from on-site generation, factory vehicles | Purchased electricity, purchased district heating/cooling | All emissions from the production and transport of purchased raw materials, subsequent emissions of products. |

Definition of scopes (source: GHG Protocol)

TOTAL CARBON FOOTPRINT

A company’s total carbon footprint is calculated by adding up all the carbon emissions from all sources (upstream, locally and downstream). Most companies focus on Scope 1 and Scope 2, because data for Scope 3 emissions are more difficult to determine.

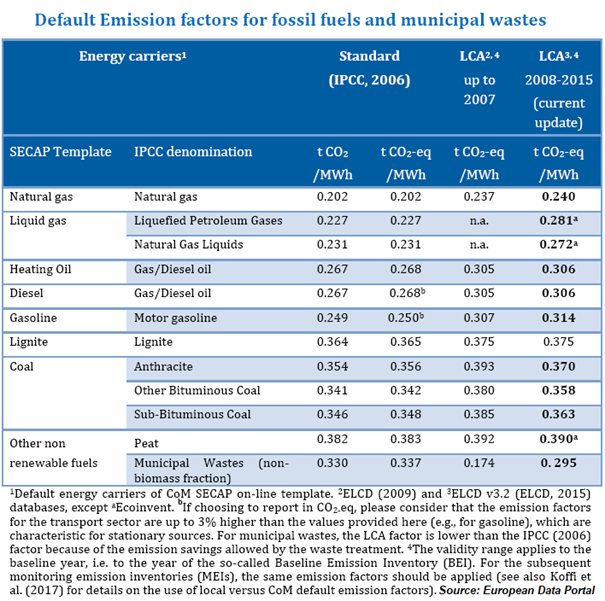

For each energy source, the carbon emission factor is multiplied by the energy consumption. For emissions due to materials used for manufacturing, the mass of material is multiplied by its corresponding emissions factors.

The emissions factors depend on location and usage. Companies should consult with local Authorities to obtain the appropriate factor.

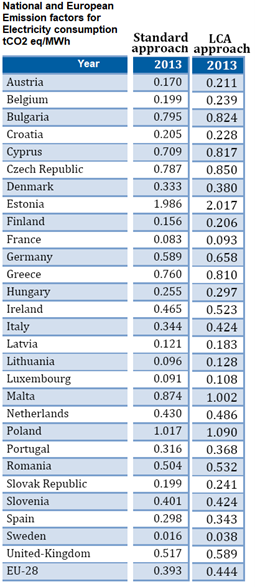

In the USA, EPA maintains a large emission factors databank. Emission factors for European countries (2017) are shown in the following tables.

It should be noted that the emission factor will very depend on the computation method. The Life Cycle Analysis (LCA), which takes into account all phases upstream and downstream of the production step, results in higher emission factors. In Europe (2013) electricity emissions factors varied widely, from 0.093 ton CO2/MWh (France) to 1 ton CO2/MWh in Malta.

DECARBONIZATION METHODOLOGY

Organizations should aim not only at minimizing their carbon footprint, but to eliminate it whenever possible. In a nutshell, decarbonization follows the following steps:

- Make inventories of carbon emissions from Scope 1 and Scope 2 from overall energy and fuel bills (and other emissions if applicable); with external suppliers and local process specialists, estimate, if possible, the Scope 3 carbon content of products;

- Focus on Scope 1 using the 4C Method (see below); identify decarbonization methods; in most situations with fossil fuel heating, electrification will be the best option;

- Examine the option of local renewable electricity generation to reduce Scope 2 emissions; if nothing can be done to generate energies presently, then purchase lower carbon energies to decrease carbon footprint;

- Work with process specialists to decrease “embedded” carbon content of the products (examples: altering the product packaging, use different raw materials or supply parts, etc.). Even if Scope 3 emissions are the most difficult to address, an increasing number of Corporations are now starting to include provisions into their purchasing policies to decarbonize their inputs. By virtue of a Domino Effect, this can only lead to more important emissions abatement.

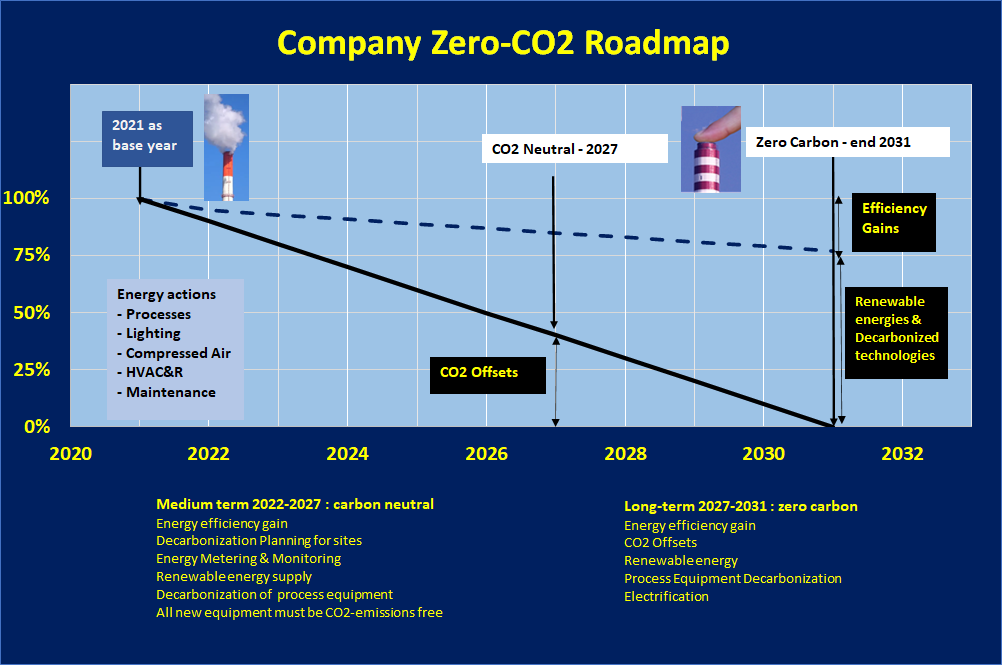

DECARBONIZATION ROADMAP

The Roadmap is a plan or strategy intended to achieve your Decarbonization goals. It should clearly state your pathway, with targets and milestones. Means to achieve your goals should preferably be known ahead of time.

The figure below illustrates the methodology. In the majority of cases, Decarbonization starts with energy efficiency measures. Energy that is not consumed needs not to be decarbonized.

FINDING ALTERNATIVES USING THE 4C METHOD

No matter what method is used, in fine, the practical approach to a decarbonization path will always be a combination of four generic alternatives, as shown in this figure.

The “4C” method was developed by Dr. A. Bensafi and can be applied to a wide range of situations. It enables non-experts to carry out a preliminary screening of alternative ways. Four questions should be asked while examining any process that generates GHGs. Available alternative technologies are then envisaged to answer these questions.

Can you cancel the emissions of GHGs?

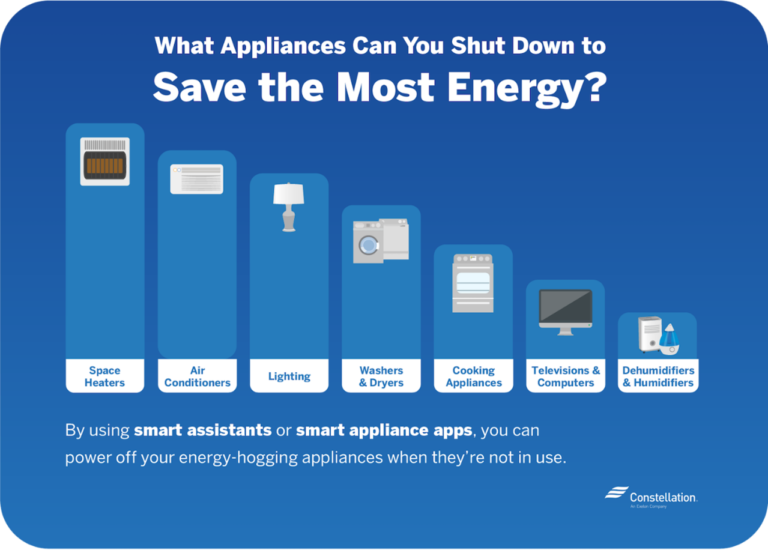

In many instances, some processes can simply be turned off. In industrial sites, a myriad of equipment stays powered even when not in use.

Sign postings to increase staff awareness

Most fume extractors remain powered all the time, even if the plant is closed. In everyday situations, the same applies in many cases. For example, people should be instructed to turn off the light when it is not needed, turn off their computer and printer when they leave work; municipalities should make sure that lighting is off during the daytime etc. Home equipment (video, TV, etc.) stays idle during most of the time – and consumes power. Hence, the “turn-off equipment when not in use” option represent an immense potential for energy savings – and therefore for decarbonization.

Equipment shut-down can be automatized by slaving switches to an equipment mains supply, or by other means (e.g., electromagnetic valves ahead of machines). Car rides can simply be cancelled if the distance is very short. Whenever a process does not consume energy or material, it does not emit GHGs.

Can you reduce the emissions of GHGs?

Substantial reductions in GHG emissions can be generated through energy conservation. In industrial site, this means setting up an Energy Savings Plan. A thorough examination of the all the consuming processes enables the identification of energy savings actions. More efficient equipment can also contribute to energy consumption reduction, while providing equal or even better service. The applications cover items such as preventive maintenance of equipment, thermal insulation for equipment or buildings, super-efficient electric motors, sophisticated controls, close monitoring, timers, presence detectors for lighting, intelligent LED lighting, and the like. Note that carbon capture from process strean is also be categorized as “cutting down” since it reduces emissions.

The “compensation mechanism”, allowing companies to purchase carbon emissions credits (also called “carbon offsets”) may also be classified in the Cut Down category. However, and because the company activities are not altered in any way, it could be qualified as a “virtual decarbonization” process since there is no practical decrease in carbon emissions. From a global point of view, carbon emissions have decreased, based on the commitments of the supplier of carbon offsets.

Carbon credits can be generated through several ways, including renewable energy projects (solar thermal heating/electricity, solar photovoltaic, wind energy, hydropower, biogas heating/electricity), energy efficiency projects (e.g energy saving products) and forestry projects (planting trees or replanting trees in a previously forested zones).

Can you change the means that emit GHGs?

by switching to different means, GHG emissions can be drastically reduced, sometimes even to zero. Examples could be: replacing gas boilers by heat pumps for space heating and domestic hot water production (and making sure that purchased electricity is from renewable sources), electrifying heating processes (e.g., in steel production), using hydrogen for welding, generating power from renewables (wind, solar, hydropower) instead of fossil fuels, replacing fossil fuels by hydrogen; changing the means could also include using a different process for production. In this context, electrification will certainly be the most powerful tool – provided electricity is provided by low-carbon emitters.

Can you capture GHGs?

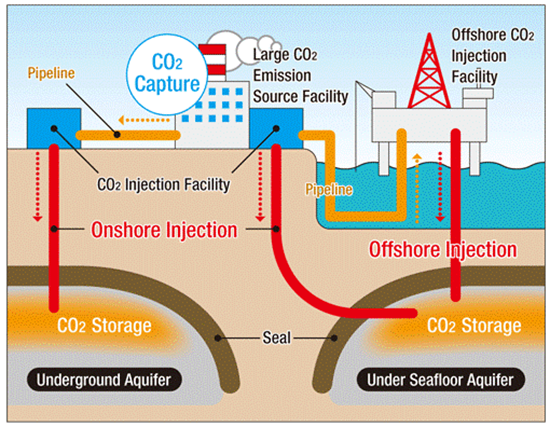

“Capture” refers to removing carbon from the atmosphere (by natural means – like growing trees), but also to removing carbon from the process exhaust streams before it is emitted (also called CCS – carbon capture and storage).

Planting trees has many advantages: they help in removing carbon dioxide from the air, storing carbon in the trees and soil, and releasing oxygen back into the atmosphere.

A second capture alternative is also possible: removing carbon dioxide from the ambient air. As of 2021, there is no consensus on the economic viability of this method and on its effectiveness (what is its environmental impact?).

Capturing carbon dioxide by removing it from process streams such as stack gases is also an option, but it requires a sink to store captured carbon dioxide. It is usually stored in geological formations, or reinjected in gas/oil wells when possible